An Overview Of Slot Tubes

Slot tubes are welcome additions to the petrochemical and food processing industry as they provide efficient filtration systems for liquid and solid separation. Aside from filtration, many industries find the slot tubes easy to maintain and with bigger filter area, makes it easier to prevent buildups.

Slot Tubes

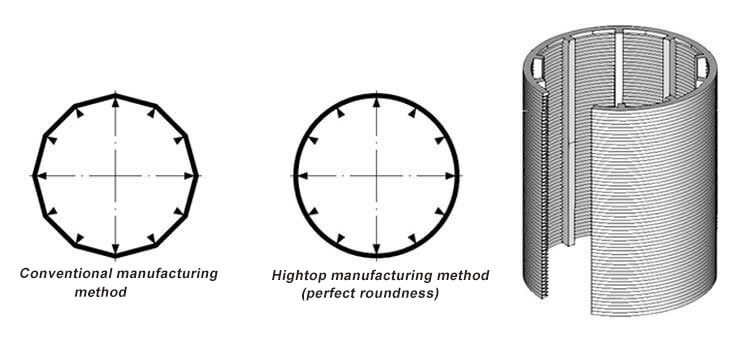

Slot tubes are typically made from stainless steel grade of 304 and 316L to ensure that chemicals that are filtered will not result to corrosion of the filters. A standard construction of a tube is made by determining the surface wire area divided by the support wire and multiplied by the number of support wires needed. The construction designation ensures a smooth and round surface while support wires ensure that the surface has proper backing. Supports are often welded together with the surface profile to add strength and reinforcement to the whole tube slot.

A surface profile of 10S for example would need a support profile of Q25 with 8 support wires spaced out equally around the slots. Customization is also available depending on the design and requirement of the customer. Reinforcements are also available and depending on the structure of the tubes can either be in spiral, cross or perforated design.

Types of Slot Tubes

There are currently three different slot tubes designs that are being made available by HighTop to customers – Radial Slot Special, Radial Slot Standard and Axial Slot Execution Special.

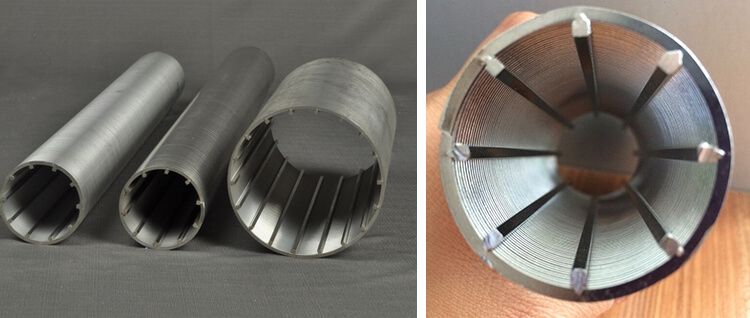

Radial slot special tubes are designed with the support bars welded inside the tubes equally spaced out to support the surface area unlike the standard design where filtration is done from the outside of the tube to the inside as the special tubes’ filtration works from the inner area towards the outer area. Another difference with the standard design is that the standard design has the profiles fused with the extensive dimension outermost to the support bars inside the tube.

In the Axial slot execution special on the other hand, the spaces in between are bigger with the profiles being paralleled to the screen cylinder. The support wires are wrapped on the outside of the slots and welded together to stay connected. The wires are often pressure welded together to ensure that they stay attached.

Aside from these slot tube types, some companies also offer conical tubes that allow filtration from the inner to outer and outer to the inner (reverse design). These tubes are preferred for industries that require filtration that can handle pressure as these tubes distribute the pressure level better. Customization of designs is also available upon request.

Benefits of The Slot Tube

Wedge wire slot tubes are beneficial for companies that demand bigger filter areas without having to worry about the possibility of buildup of impurities. Standard tubes are created with a minimum gap of 20 microns between profiles making it easier to remove impurities without clogging. Easy maintenance is also observed with slot tubes through the use of back flushing techniques. Slot tubes can be made into end products such as resin traps, scale trap baskets/internal reactors and nozzles.

For more information on slot tubes, please contact us today. You can also request for a sample of the product material.