Water is important to all living beings. Humans in fact can go for more than 3 weeks without food; however, since the body is made up of 60% water, a human being can only last 3 days without water which is when dehydration sets in. As drinking water is the main source for living beings, a clean water source is important.

The source of clean water is important; however as the human population grows, sources become scarce and clean water resources are hard to find. This is where waste water treatment plants come into play. Waste water treatment plants have evolved considerably over time and become sophisticated and advanced with the technology and equipment that they use even though the process still remains the same.

Bacterial Presence in Drinking Water

Coliform bacteria is the most common bacteria that can be found in drinking water. Although relatively harmless in small numbers, the presence of these bacteria may indicate the threat disease and even outbreaks. Examples of bacteria harmful to humans and animals are E. coli and fecal coliform. These bacteria come from fecal matter and can cause severe illness and in some instances, death. To ensure that treated water is free from these microorganisms, strict quality control and use of advanced technology and equipment are used.

Treatment Process Using Wedge Wire

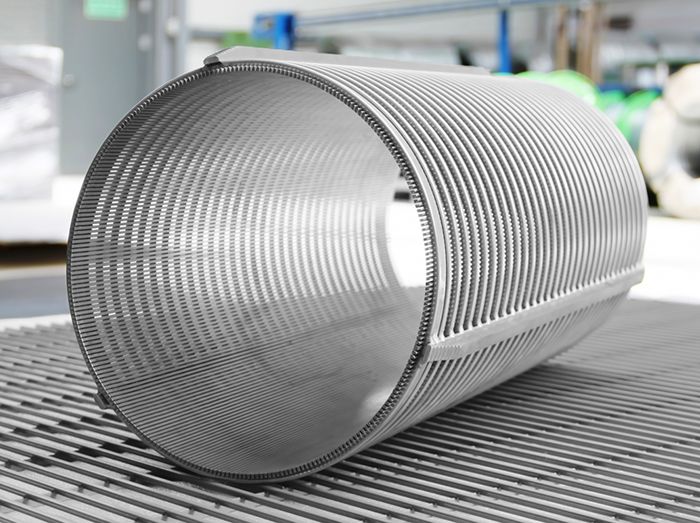

Waste water comes not only from residential and commercial pipelines but also from industrial ones. Before being released back to the water stream, waste water undergoes screening and filtration. Screening includes removal of solid particles from liquid. In this process, wedge wire filter screens are used to remove the solid materials such as bottles, cups, clothing materials and plastics.

As some materials might be corrosive or contain harmful chemicals, screens or filters must be made of stainless steel grade material of 304L to ensure that the filter screens won’t break down during the separation process. Some wedge wire screen head widths differ depending on how big or small the concerned plant wants. This prevents clogging and at the same time ensures efficiency in the filtration. A reinforced screen is a must especially for plants that require heavy duty work. Once all visible solid materials are removed, the remaining waste will be sent to treatment.

The secondary treatment involves the removal of sludge that has settled at the bottom of the filtration. Since the water still contains waste that needs to be broken down, bacteria and other microorganisms are introduced to break down the sludge. Some plants may use centrifugal pumps to mix the sludge and microorganisms to activate the latter and start the aeration process.

After the breakdown, the remaining water is then treated to ensure that the water quality is safe and free from harmful microorganisms before being released to water streams. Some plants have disinfection processes to ensure that the number of microorganisms in the water is reduced.

Benefits of Wedge Wire Screen Filter

As millions of waste water is being produced every day, the demand for waste water facilities is booming. That said, because of the delicate nature of the process, strict compliance to safety and guidelines must be observed to ensure safe drinking water for everyone. Wedge wire filter screens play a crucial role to ensure safe and quality drinking water. Below are some advantages of using Hebei HighTop filter screens.

- Customized head width. Due to different needs and requirements, the filter’s head width is customizable. This is important as not all treatment plants process the same kind of materials. Some plants may process residential sewage while other plants process both residential and commercial wastes. Other plants may only be for exclusive industrial use. The overall capacity may also affect the sizes of the profile surface(s) needed. As each design and preference is important, our expert team can help clients with their designs and manufacturing needs.

- Material used. Stainless steel grade is the preferred material when filter screens are used for industrial applications. That said, some plants may require special reinforcement(s) to their filter screen and also require additional coating to prevent corrosion from chemical exposure. Hebei HighTop can apply abrasive coating to the wedge wire screens to comply with the needs and requirements of our customer.

- Resiliency. Volume capacity can break even the toughest materials without proper reinforcement. That said, our filter screens are made from stainless steel material ensuring that the screens will meet even the most demanding needs. For bigger capacity loads, reinforcements are available. The reinforcement would support the profile of the screen thus increasing its service life.

- Low Maintenance. For companies that are looking for an economic and efficient solution to their everyday needs, the wedge wire screens are non-clogging and easy to clean with the use of back flushing.

- Precision Slots. One of the best things about Hebei HighTop’s wedge wire screens is its product’s precision profile depths. Each wire head width varies depending on requirements; however the standard ones range from 0.6mm to about 7.00mm in width. The slot gap is from .25mm – 20mm and the profile depth is from 1.3mm to 10mm. The precision features allow for better filtration as all surface profiles are uniform.

Use of Wedge Wire Filter Screen vs. Other Filtration Products

When it comes to traditional and modern filtration products, wedge wire screens are better products in that they are more resistant to corrosion due to the stainless steel material. It can also withstand sudden drops or increases in temperature as well as extreme pressure. This runs in contrast with the use of traditional products such as perforated plates or woven wire mesh screens.

Wedge wire filter screens not only benefit the waste water treatment plants but they can also be used in other different industries that would require precise and efficient filtration systems. Aside from water treatment plants, filter screens may also be used in the oil and chemical industry, mining, food and beverage and other industrial applications.

For more information on wedge wire screens or to request for a free sample, please email or contact us.